Toyota Promises BEVs With Giga Castings and 932-Mile (1,500-Km) Range by 2028

The world's largest car company has tried to say several times it would only follow this path when battery technology was at the right stage. Considering what the company disclosed in its "Let's Change the Future of Cars" workshop, that stage will arrive in 2026, leading to battery electric vehicles with a range of 932 miles (1,500 kilometers) by 2028. Oh, and the cars will have giga castings, just like those Tesla developed.

Toyota's BEV revolution will start in 2026 with a new-generation square lithium-ion battery. By square, read prismatic. Called the performance version, these new cells will double the range provided by the ones installed on the bZ4X, which will allow a new BEV to also be introduced in 2026 to offer 621 miles (1,000 km) of range and cost 20% less than the current ones. And that will be just the beginning.

The Japanese carmaker will later premiere a bipolar lithium iron phosphate (LFP) battery that will offer 20% more range, 40% less cost and a similar charging time as the bZ4X – 30 minutes to go from 10% to 80% of charge. Toyota calls it the popularization version. That means that an SUV similar to the bZ4X with bipolar LFP cells in its battery pack would run 302 miles in an EPA cycle instead of the 252 miles it now delivers. If we consider the WLTP cycle, it would be upgraded to 619 km (385 mi). Nowadays, the bZ4X can provide up to 516 km (321 mi). In the CLTC cycle – for China – the bZ4X presents a maximum range of 615 km (382 mi). The 20% boost would improve that to 738 km (459 mi) – with LFP batteries, mind you.

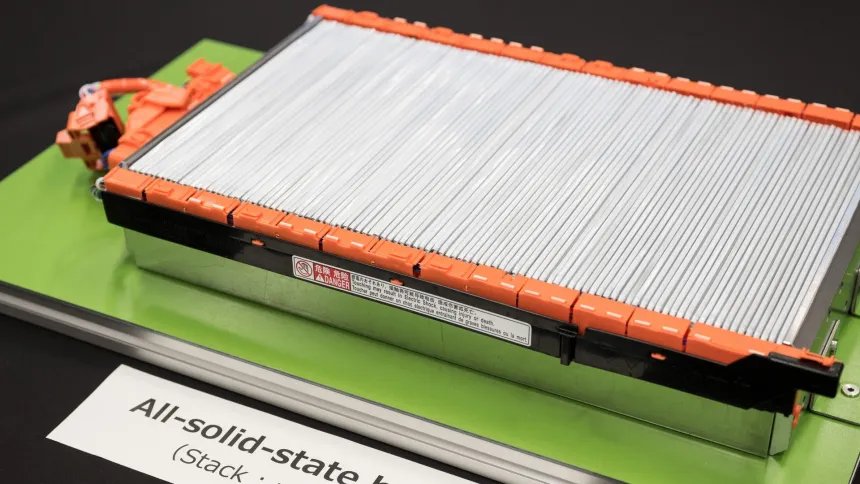

The bipolar technology will also include NMC cells. Toyota will present its ternary lithium-ion cell with a high nickel cathode by 2027. Looking at its numbers, they are not as impressive as those exhibited by the previous batteries: only 10% of range gains and cost reductions. On the other hand, it will save 10 minutes in the fast-charging process: 20 minutes to go from 10% to 80% instead of 30. The true game-changer will be solid-state cells.

Toyota's first generation should debut in 2027 or 2028 with a 20% better range than that presented by its first-generation performance cells. In other words, it will deliver 745 miles (1,200 km) of range instead of 621 miles (1,000 km). Fast-charging times from 10% to 80% of total capacity should demand only 10 minutes. The Japanese carmaker is already working on a second-generation solid-state battery that should arrive after 2028. This is the one that will offer 50% more range than the performance cells – or 932 miles (1,500 km) of range.

These figures are obviously just a way to demonstrate the evolution leaps Toyota's future BEVs will have. With more energy-dense battery packs, they can be lighter with slightly lower ranges. The world's largest car company will also look for other ways to make its BEVs more efficient, such as delivering them with aerodynamic coefficients of less than 0.2. The company said it is targeting 0.1 with a "new technology to reduce aerodynamic drag in any shape" developed with Mitsubishi Heavy Industries. If Toyota is able to deliver that, it should be groundbreaking. The company is also working on a smaller eAxle. That could save space for more cargo and also allow rear passengers to sit lower, which has a direct impact on aerodynamics.

Perhaps the most surprising element Toyota shared in its workshop was stating it would use giga castings to build its EVs. That's something Tesla has been doing since it presented the Model Y. The goal is to save production time, which will bring BEV prices down. In the images Toyota disclosed, the massive cast parts seem to be only structural, built in a pretty different way than those from Tesla. The Japanese carmaker said it has "reviewed the structural design to make it simpler and slimmer." It also noted that "reducing the number of parts and processes" is something that "reflects the TPS philosophy of eliminating waste in each process." Tesla Production System?

Joking aside, it will be interesting to see Toyota apply Tesla's idea to car manufacturing while taking repairability and dependability into account. The Japanese carmaker did not elaborate on those aspects. It also did not mention whether these new battery packs will be easily repairable or how long they will last. If we are to consider the 1-million-km or 10-year warranty it gave the bZ4X, it may be pretty confident about the new cells.

Toyota also wants to eliminate conveyors to create a "self-propelling assembly line." In other words, the vehicles will move by themselves to the next production station through "sensors and control systems on the factory" that will communicate with the cars "to control them from the outside." If Toyota manages to do that, it will save billions in manufacturing preparations for the production of any new vehicle. At the same time, it will have to care a lot for data safety to prevent interferences with the cars in production lines and when they reach their new owners' hands as well. It will look like an alien dreadnought, something Elon Musk tried to create before making the Model 3 in tents.

Related News